Sustainability

‘There is a big demand for fabric printing’

Caterpillar is making huge investments to meet the soaring demand for green printing

Caterpillar, a printing and finishing solutions service provider, makes huge investments to meet the soaring demand for green printing. The OOH solution provider has installed two EFI machines, a GS EFI GS3250LX PRO UV Hybrid and a GS5250 LXR five-meter roll-to-roll kit for outdoor and indoor signage business. The company also has an EFI Reggiani, a dye-sublimation printer for soft signages, flags and banners.

Caterpillar, a printing and finishing solutions service provider, makes huge investments to meet the soaring demand for green printing. The OOH solution provider has installed two EFI machines, a GS EFI GS3250LX PRO UV Hybrid and a GS5250 LXR five-meter roll-to-roll kit for outdoor and indoor signage business. The company also has an EFI Reggiani, a dye-sublimation printer for soft signages, flags and banners.

Nishant Shah, managing director at Caterpillar, said, “There’s a big demand for fabric printing and with the Reggiani running speeds of up to 400 sqm/hour, finishing became our biggest hurdle. Cutting the fabric to shapes and accurate sizes quickly and accurately manually would generally create a backlog. This led us to the decision of investing in a digital finisher which would fulfil all our cutting and finishing needs.”

Nishant Shah added, “The new kit will help us eliminate finishing bottlenecks as well as reduce wastages and losses.”

The 3.2×3.2 metre MCT VersaTech2 is equipped with TigerVision, a vision system for accurate scanning and cutting printed graphics built on a single screen software interface. The VersaTech2 is capable cutting aluminium, vinyl/plastic badges, labels, rolled vinyl, semi-rigid plastics, flexible circuits, rolled fabric, rigid boards, plastics and composites, packaging and cardboard materials, structural materials including point-of-purchase, foams of varying densities and thicknesses, and banner material.

-

People

PeopleCKA Birla Group appoints Himanshu Khanna as Group Chief Marketing Officer

-

Creative Concepts

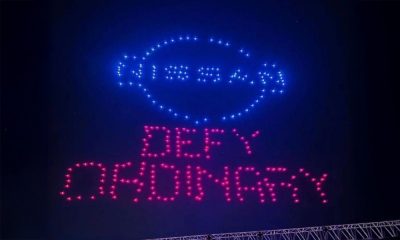

Creative ConceptsNissan paints the sky over Udaipur to unveil its latest car

-

Campaigns

CampaignsNetflix promotes ‘The Night Agent- Season 3’ with cheeky post-Valentine’s OOH billboard

-

Insights

InsightsBuilding the case for a Data-by-Design approach in DOOH